Hydraulic cylinders are essential components in many different industrial applications. They provide linear force and motion by converting pressurized hydraulic fluid into mechanical work.

Different types of cylinders differ by construction, internal designs, mounting configurations, and other factors. The most common cylinder styles include ram style, tie rod, and welded.

Lifting

At their most basic, hydraulic products are all about turning trapped fluid pressure into a powerful push or pull. You see them everywhere in modern machinery, whether big metal claws lifting cars at the scrapyard or precise machines whirring away in factories.

A hydraulic cylinder’s force depends on the volume and pressure of the fluid in its chamber and its rod and bore dimensions. It also needs to have a reservoir, which holds the fluid before it gets pumped into the cylinder and returns it after use.

Cylinders can be single or double-acting. Single-acting cylinders have one side that receives pressurized hydraulic fluid, while the other relies on external factors like gravity or a spring mechanism for return motion.

Pushing

Hydraulic cylinders can be used to push objects. They are commonly found in construction equipment such as bulldozers and cranes. They can also be found in agriculture equipment like plows and wood splitters.

They can also be designed to work at different speeds during the same stroke. They are ideal for applications such as power steering, where a constant force must be applied over a long period.

Specialist seals, often with backup rings, are also used to handle extreme pressure and resist corrosion. They are usually made of stainless steel. They can also be welded or screwed onto the cylinder barrel.

Pulling

Hydraulic motors and cylinders can deliver powerful forces for pulling and lowering operations. They’re used in manufacturing machinery to help with metalworking, plastic molding, and other production processes. They also work in heavy equipment like tractors, construction machinery, and mining machines.

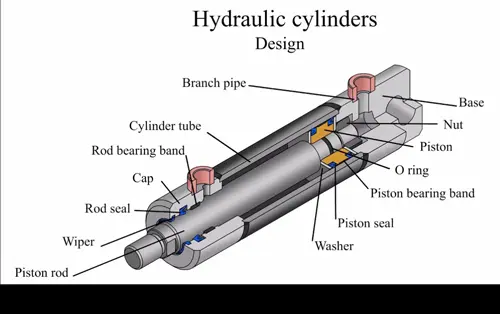

The barrel or cylinder tube is built to withstand hydraulic fluid pressure throughout its life. It’s constructed from various materials, including carbon steel and aluminum.

Cylinders that operate at high temperatures will require specialist seals to ensure they won’t melt.

Tightening

Cylinders are used for various applications including tightening, pressing, holding, lowering, and clamping. Identifying what work you need to do can help narrow your options and find the perfect hydraulic cylinder.

A hydraulic cylinder is steel and can withstand pressure inside its walls. It will also have a rod that extends and retracts based on the hydraulic fluid being pumped to either end of the cylinder.

The rod is commonly coated with hard chrome plating or a corrosion-resistant coating. It can also have a flange or screw connection to the head. Special seals will be designed for specific cylinder applications, considering the type of environment and work that will be done.

Turning

Hydraulic cylinders are often used for material handling in warehouses and construction. They are also found in equipment that needs to stay in place, such as jack-up drill rigs and floating oil platforms.

Cylinders are usually made from carbon steel that can handle hydraulic fluid pressure inside their walls. They may be coated with different coatings to withstand specific operational conditions, such as those in the mining industry with impact from stones and salt water.

Tie rod style cylinders use high-strength threaded rods to connect the two end caps of the cylinder. They’re an excellent choice for applications that require low-height cylinders and have the benefit of easy maintenance.